Why Just only Replacing the Mechanical Seal is a Costly Mistake

We recently received a new vertical centrifugal pump for overhauling with the remarks of seal leaking. The pump data is: Jiangsu Yancheng Ocean Pump, Model PVH 100-2501Z—rated for 150M3 and 80 Meter head, driven by a 55 KW motor. Everything looked brand new, yet within a short period of operation, we found a significant leak. The mechanical seal had failed catastrophically.

The immediate question:

How could a brand-new, correctly specified pump fail so quickly?

The Investigation:

Opening the Pump

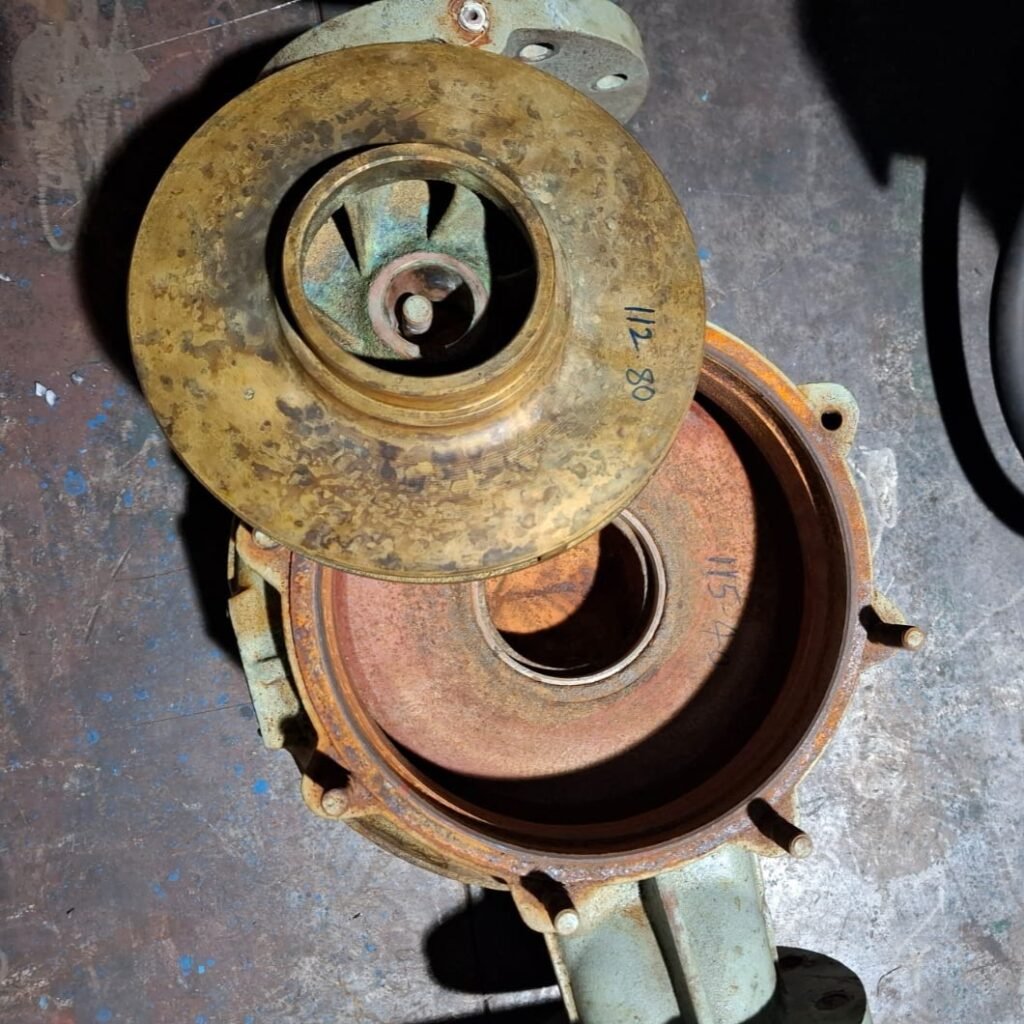

Upon disassembly, we confirmed the mechanical seal was broken, requiring immediate replacement. However, we know that seals don’t fail for no reason; they are often victims of a deeper issue. Our investigation turned to the internal pump components, specifically the wear rings, bearings, and the shaft and motor’s free rotation.

Critical Measurement:

We measured the running clearance between the impeller and the casing wear ring. For a pump with a 250 mm Impeller OD, we expected clearance in the range of 0.25 mm to 0.45 mm (nominal). The actual measurement shocked us: 2.6 mm of clearance.

Analysis of Other Components:

- Electrical Motor: The motor was freely rotated. Conclusion: No primary issue found with the electrical motor.

- Bearings: Found to rotate freely, but there was a light burning mark. This suggests that the shaft could have been subject to excessive movement or ‘shaking’ while running, placing undue stress on the bearings.

- Pump Shaft: Found a minor scratch in one area. This is not in a critical sealing zone and could be used back as the scratch is not in a condition bad enough to require immediate replacement.

What are the points that could have caused this problem?

Based on our findings, we identified the following possibilities that led to the seal failure:

- Improper Assembly of the Seal: Incorrect installation or handling of the mechanical seal could lead to easy breakage.

- Improper Motor Coupling/Alignment: Poor motor-to-pump alignment can induce severe vibration and shaft deflection, causing the mechanical seal to be broken.

- Excessive Wear Ring Clearance (The Most Likely Root Cause):

We could possibly say the wear ring clearance is the major contributor here. The measured 2.6 mm is far more than the nominal clearance of 0.25 mm to 0.45 mm. This excessive gap destroys the vital hydraulic stabilizing effect that the rings provide. Without this stability, the impeller (rotor) experiences high radial forces, leading to severe shaft vibration and runout.

This vibration directly impacts the mechanical seal, causing the precision faces to separate, overheat, and fail prematurely. It is also the likely cause of the light burning mark found on the bearing.

The Fix:

The high likelihood is that the 2.6 mm wear ring clearance is the root cause of the vibration and subsequent seal failure.

If we assemble the pump in the same condition, there is a very high possibility that the new mechanical seal will be damaged again within a short period of time.

The issue must be rectified first. The solution requires:

- Replacing the wear rings to achieve the manufacturer’s nominal clearance 0.4 mm.

- Replacing the damaged mechanical seal.

- Ensuring the motor-to-pump coupling alignment is checked and perfected before restart.

This experience highlights a crucial lesson: in pump troubleshooting, a broken seal is often a symptom, not root disease. Always investigate the internal components, especially wear rings—to ensure long-term reliability.

*********************************************************************************************************